Fabric Inspection:

Fabric inspection is a tool for satisfying internal as well as external customer. External customer can benefit by getting the products as per the specification provided while internal customer benefit by knowing the reason for any down-gradation and can thus correct the same. Fabric inspection also mirrors the packing percentage and associated value losses due to down-gradation. There are many inspection systems and of them four point inspection system has got wide acceptance and is followed globally by fabric and garment manufactures. This article is an attempt to highlight the advantages, procedure of four point inspection system and using the generated data for grading of the fabric.

Fabrics have certain desirable characteristics depending on end use. Various defects in the fabric either mar the appearance or adversely affect some of these desired characteristics. Thus fabric produced must be inspected before releasing it for dispatch so that the proper quality goods reach the customers.

Objective of Fabric Inspection:

The objective of fabric inspection is to ascertain whether the fabric received is ol" I he expected Quality standard or not. The main objective is detection of fabric defects and nonconformance as early as possible. So that the time and money are not wasted in the manufacturing, process. The ultimate goal of any quality control activity in clothing' industry is to satisfy the customers.

Importance of Fabric Inspection:

As we know that fabric are the main and costly raw materials of a garment. So it is very important to use fabric efficiently and control wastage of fabric. On the other hand fabric defects are the maximum defects of garments, for which many-unexpected problem may occur in a clothing industry. Such as- short shipment, discount, low price etc.

To avoid all above problems and to take preventive measures fabric inspection is very important for a clothing industry. It is also important for the following aspects:

1) Improve product quality

2) Minimize waste

3) Reduce the cost

4) Avoid short shipment/Order cancellation.

5) Increase productivity

A fabric inspection only addresses itself to patent defects because they are the ones which can be recognized by a reasonable inspection. Any reasonable inspection can be performed by using Grading System.

Inspecting conditions

Sample Inspection- The best is 100% but could be costly. As an alternative a smaller sample size could be decided considering the available time, space, equipment and staff. Often a 10% sample is inspected to obtain an estimate of the quality. In inspecting a sample, a representative sample should be drawn at random. A stratified sample-would give a better picture.

The inspected results would depend on the conditions under which the inspection is performed. It is essential to indicate these conditions when preparing a report.

(1) light- top light the light recommended is two fluorescent tubes, 40 w, parallel to each other, perpendicular to the direction of the fabric, about 4 feet above the surface, back light defused light.

(2) Speed a speed of 15 - 20 yds. per minutes is normally used, but should be decided on (he. type of fabric, nature of the defects and the end use.

Inspection

Inspection in reference to the apparel industry can be defined as the visual examination or review of raw materials (like fabric, sewing threads, buttons, trims, etc), partially finished components of the garments and completely finished garments in relation to some standards. The main objective of inspection is the detection of the defects as early as possible in the manufacturing process so that time and money are not wasted later on in either correcting the defect or writing off defective garments.

Purpose of fabric inspection

Fabric Inspection is an important aspect followed prior to garment manufacturing to avoid rejects due to fabric quality and facing with unexpected loss in manufacturing. Fabric inspection is done for fault/defect rate, fabric construction, end to end or edge to edge shading, colour, hand or feel, length/width, print defect and appearance. Fabric inspection ensures to minimise the rejection of cut panels or rejected garments due to fabric faults. Cutting inspected and approved fabric ensures not only finished garment quality but also reduces rejects, improves efficiency and timely deliveries.

The purpose of fabric inspection is to determine the quality and acceptability for garments. As fabric is received, it should be inspected to determine acceptability from a quality viewpoint. Some garment manufacturers rely on their fabric suppliers to perform fabric inspection and fabric defects. In many small companies, spreading and cutting is done by the same personnel and fabric is inspected as it is being spread on a table for cutting.

Fabric inspection, mapping or marking defects is important prior to spreading and cutting because:

-

Spreading can be done more quickly because the spreader is not also inspecting the fabric.

-

A cutter's productivity will increase because the defects are already marked.

-

The patterns are cut around the defects so as not to include them in the finished garment.

Fabric inspection machines

Fabric inspection is usually done on fabric inspection machine. These machines are designed so that rolls of fabric can be mounted behind the inspection table under adequate light and rerolled as they leave the table.

Defects can be seen readily with these machines, as the inspector has a very good view of the fabric and the fabric need not be reversed to detect defects. These machines are power driven or the inspector pulls the fabric over the inspection table. The defects are located, marked and recorded on an inspection form. These machines are also equipped to accurately measure the length of each roll of fabric as well as monitor the width of the fabric. The variation in width of fabric can result in a higher cost of manufacturing for basic garments since profit margin for these garment manufacturers is usually lower than that for fashion garment manufacturers and therefore, maximum fabric utilisation is vital.

How much to inspect?

When a sewing factory receives fabric from the mill, it is difficult to conduct a full 100% inspection of the fabric. A minimum 10% inspection of all piece goods prior to spreading the fabric is recommended.

Grading Systems:

There arc-different types of standard grading systems in practice. A system is agreed or selected by mutual acceptance between supplier and buyer. Some of the available grading systems are given below:

(a) 4 point system

(b) 10 point system

(c) Graniteville '78' system

(d) 6 point system

(e) Dallas system

Ten Point System

It was developed in the 1950's. This system assigns penalty points to each defect, depending on the length of the defect.

Penalty points are assigned as per the following:

Warp direction

Length of Defect |

Penalty points |

Up to 1" |

1 |

1"- 5" |

3 |

5" – 10" |

5 |

More than 10" |

10 |

Weft direction

Length of Defect |

Penalty points |

Up to 1" |

1 |

1"- 5" |

3 |

5" - half width |

5 |

More than half width |

10 |

Under the Ten-Point System, a piece is graded a "first" if the total penalty points do not exceed the total yardage of the piece. A piece is graded a "second" if the total penalty points exceed the total yardage of the piece.

The following points are noteworthy:

-

This system is bit complicated because points per length are different for warp and weft defects.

-

It is difficult in practical use.

Graniteville "78" system

This system was introduced in 1975 for the field of fabric grading. The system divides defects into major and minor types .The major defect is one, which is very obvious and leads the goods to second quality. The minor defect is one, which may or may not have caused garment to second, depending on its location in the end use item.

Penalty Points are assigned as per the following:

Length of Defect |

Penalty points |

Up to 9" or 25cm |

1 |

9"- 18" or 25-50cm |

2 |

18" – 27" or 50-75cm |

3 |

27" – 36" or 75-100cm |

4 |

The following points are noteworthy in this system:

-

The principle was established in garment cutting piece, in which, the short length defects (less than 9") will normally be removed.

-

The system tries to balance the importance of longer defects (over 9") and put less weight on 1-10" defects such as slubs.

-

The system also suggests the viewing distance of 9 foot instead of normal 3-foot viewing distance.

-

The system tends to eliminate very small defects from the total penalty score.

-

This is mostly recommended for use, where larger garments are to be cut with fabrics of wider widths.

6 Point System

6 point’s arc assigned according to size of defects.

Length of Defect |

Penalty points |

0 - 25cm |

1 |

25-50cm |

2 |

50-75cm |

3 |

75-100cm |

4 |

100-125cm |

5 |

125-150cm |

6 |

Some European buyers use this method and express the quality level based on 100 sq. mtrs.

Dallas System

This system was developed in 1970s specifically for knits. It was approved by Dallas Manufacturers Association. According to this system, if any defect was found on a finished garment, the garment would then be termed as a "second". For fabrics, this system defines a second as "more than one defect per ten linear yards, calculated to the nearest ten yards". For example, one piece 60 yards long would be allowed to have six defects.

4-Point System

The 4-Point System, also called the American Apparel Manufacturers (AAMA) point-grading system for determining fabric quality, is widely used by producers of apparel fabrics and is endorsed by the AAMA as well as the ASQC (American Society or Quality Control).

The 4-Point System assigns 1, 2, 3 and 4 penalty points according to the size and significance of the defect. No more than 4 penalty points can be assigned for any single defect. Defect can be in either length or width direction, the system remains the same. Only major defects are considered. No penalty points are assigned to minor defects.

In this system, one should inspect at least 10 per cent of the total rolls in the shipment and make sure to select at least one roll of each colour way.

Fabric defects are assigned points based on the following:

Warp and Weft Directions

Warp and Weft Directions

Length of Defect |

Penalty points |

Up to 3" |

1 |

3"- 6" |

2 |

5" - 9" |

3 |

More than 9" |

4 |

For Hole & Opening(1 inch or Less) |

2 |

For Hole & Opening(Over 1 inch) |

4 |

Total defect points per 100 square yards of fabric are calculated and the acceptance criteria is generally not more than 40 penalty points. Fabric rolls containing more than 40 points are considered "seconds".

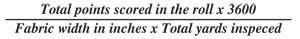

The formula to calculate penalty points per 100 square yards is given by:

The following are noteworthy points for this system:

-

No more than 4 penalty points can be assigned for any single defect.

-

The fabric is graded regardless of the end-product.

-

This system makes no provision for the probability of minor defects.

-

4 point system is most widely used system in apparel industry as it is easy to teach and learn.

General Inspection Procedures

-

Fabric inspection is done in suitable and safe environment with enough ventilation and proper lighting.

-

Fabric passing through the inspection frame must be between 45 - 60 degree angles to inspector and must be done on appropriate Cool White light above viewing area. Back light can be used as and when needed.

-

Fabric speed on inspection machine must not be more than 15 yards per minute.

-

All fabric inspection must be done when 80% of good or lot is received.

-

Standard approved bulk dye lot standards for all approved lots must be available prior to inspection.

-

Approved standard of bulk dye lot must be available before starting inspection for assessing colour, hand, weight, construction, finish and visual appearance.

-

Shade continuity within a roll by checking shade variation between centre and selvage and the beginning, middle and end of each roll must be evaluated and documented.

-

Textiles like knits must be evaluated for weight against standard approved weight.

-

Fabric width must be checked from selvage to selvage against standard.

-

All defects must be flagged during inspection.

-

The length of each roll inspected must be compared to length as mentioned on supplier ticketed tag and any deviation must be documented and reported to mill for additional replacement to avoid shortage.

-

If yard dyed or printed fabrics are being inspected the repeat measurement must be done from beginning, middle and end of selected rolls.