Knitting:

Knitting is a process of fabric forming by the intermeshing of loops of yarns. When one loop is drawn through another, loop stitch is formed. Stitches may be formed in horizontal or vertical direction.

A knitted fabric may be made with a single yarn which is formed into interlocking loops with the help of hooked needles. According to the purpose of the fabric, the loops may be loosely or closely constructed. Crocheted fabric is the simplest example of knitting where a chain of loops is constructed from a single thread with the help of a hook. As the loops are interlocked in a knitted fabric, it can stretch in any direction even when a low-grade yarn having little elasticity is used.

Basic Construction Process of Knitted Fabric

The construction of knitted fabric is assessed by the number of stitches or loops per square inch. When the interlocking loops run lengthwise, each row is called a wale that corresponds to the direction of warp in woven fabrics. When the loops run across the fabric, each row is called a course that corresponds to the filling or weft in woven fabrics. A knitted fabric having 50 loops or stitches in one inch of width and 60 loops in one inch of length will be said to have 50 wales and 60 courses.

The construction of knitted fabric is assessed by the number of stitches or loops per square inch. When the interlocking loops run lengthwise, each row is called a wale that corresponds to the direction of warp in woven fabrics. When the loops run across the fabric, each row is called a course that corresponds to the filling or weft in woven fabrics. A knitted fabric having 50 loops or stitches in one inch of width and 60 loops in one inch of length will be said to have 50 wales and 60 courses.

Types of Knitting:

The two main forms of knitting

-

Weft knitting

-

Warp knitting

1) Weft knitting:

Weft knitting is a method of forming a fabric in which the loops are made in horizontal way from a single yarn and intermeshing of loops take place in a circular or flat form on across wise basis. Most of the weft knitting is of tubular form.

There are three basic stitches in weft knitting

-

Plain-knit stitch

-

Purl stitch

-

Rib stitch

Any other stitch is a variation of these three stitches. Hand knitting is basically weft knitting. When done on weft knitting machines, individual yarn is fed to a single or multiple needles at a time.

Plain-knit stitch:

Plain knit, the basic form of knitting can be produced in flat knit or in tubular (or circular) form. It is also called jersey stitch or balbriggan stitch. A row of latch or beard needles is arranged in a linear position on a needle plate or in a circular position on a cylinder. The side by side evenly spaced needles are moved by cams, which act on the needle butts. The spacing of the needles is called gauge, gage or cut which refers to the number of needles in one and a half inches, for example, a 60 gauge machine will have 40 needles per inch. The needles intermesh loops drawn to one side of the fabric, forming vertical herringbone like ribs or wales on the right side or technical face of the fabric. On the reverse side or the technical back, courses are visible as interlocking rows of opposed half circles. These fabrics have the tendency of curling up at the edges which is controlled to a level through certain finishes.

Plain knit allows the use of single or plied yarns produces comparatively lightweight fabrics than produced by other stitches. The production rate is higher, about 5 times more than weaving. It is inexpensive and a variety of designs may be produced including stripes, multicolored patterns, textured surfaces produced by raised designs and pile effects. Plain-knit fabrics stretch more in the width than in the length and as such, they are widely used for making underwear, gloves, hosiery and sweaters.

Example:

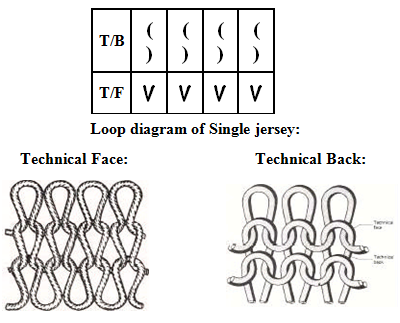

Single-Jersey Fabric

It is a plain single knit structure with face loops on one side and back loops on the other. The structure is produced when all the needles of a single bed machine knit at each feed. This structure can be of technical face or technical back.

Properties/Identification:

-

Appearance: Technical face has V shape stitch/ jersey stitch and Technical back has semi-circle stitch.

Stitch diagram of Single Jersey:

-

Semi circle stitch is also known as purl stitch because it looks like purl.

-

Edge curling: Normally occurs T/F to T/B in lengthwise direction but sometimes occurs T/B to T/F in widthwise direction. The reason of it is yarn tension/ torque because the back needles were inactive during manufacturing.

-

Edge curling is a disadvantage because it hampers productivity in linking section.

-

Tension is a tightness or looseness factor of knitted structure.

Remedies of edge curling:

-

After knitting before linking use iron at the edges.

-

We can also use folder or attachment during linking.

-

Dimensional stability: Dimensional stability is comparatively poor than other knit.

-

Dimension means shape. After stretching the fabric if it recovers to original shape dimensional stability is good and if does not recover properly stability is poor.

Methods of increasing dimensional stability:

-

Increase loop density (for both light & heavy knit fabric)

-

Apply resin finish (for light knit fabric, if buyer required because it stiff the fabric)

-

Unraveled: We can unrope the yarn from the both end.

-

Elasticity (stretch ability): Almost same/ equal elasticity both in lengthwise and widthwise direction.

-

Laddering: Laddering can be repaired in flat bed knitting but not in circular knitting.

It is a defect which occur because of-

-

Needle head broken. So needle cannot catch the yarn and yarn loops slips.

-

Poor quality yarn which has slub.

-

Loose tension.

Rib stitch:

Rib stitch produces alternate lengthwise rows of plain and purl stitches and as such the face and back of the fabrics are a look-alike. Rib stitch can be produced on a flat rib machine as well as circular rib machine. In the flat rib machine, one set of needles is placed opposite the other set of needles in an inverted V position. In the circular rib machine, one set of needles is placed vertically in a cylinder and the other set of needles is placed horizontally on a dial. In both the machines, one set of needles pulls the loops to the front and the other set of needles pulls the loops to the back of the fabric. Each set of needles alternately draws loops in its own direction, depending on the width of the rib desired. For instance, rib stitches can be 1X1, 2X2, 2X1, 3X1, and the like. Accordion rib is the combination of 1x1 and 2X2. As a greater amount of yarn is required for rib stitch and the rate of production is also slower, it is an expensive method of fabric construction. The fabric doesn't curl at the edges and as the fabric possess an excellent widthwise elasticity, it is widely used for making such clothing that needs an excellent fit such as wristbands of sleeves and waistbands of garments, underwear and socks for men and children.

Example:

Rib Fabric

The word ‘rib’ derives from animals’ ribs. In this structure needle heads are not facing directly each other. Rib fabrics are composed of loops formed in opposite direction. Various types rib construction are there but common structure are 1×1, 2×2 and above 2×2 construction like 3×3, 4×4, 5×5 fancy rib but 6×6 has special name like Derby rib.

In rib structure, each course having one face and one back loop, with succeeding courses identical to the first one, having alternating wales of face and back loops.

Properties/Identification:

-

Appearance: Both sides are same in appearance. Semicircle loops can be observed in between V shape loops.

Stitch diagram of 1Î1 Rib:

T/B |

( ) |

V |

( ) |

V |

T/F |

V |

( ) |

V |

( ) |

Stitch diagram of 6Î6 Derby Rib:

T/B |

( ) |

( ) |

( ) |

( ) |

( ) |

( ) |

V |

V |

V |

V |

V |

V |

( ) |

( ) |

( ) |

( ) |

( ) |

( ) |

T/F |

V |

V |

V |

V |

V |

V |

( ) |

( ) |

( ) |

( ) |

( ) |

( ) |

V |

V |

V |

V |

V |

V |

Loop diagram of 1Î1 Rib:

-

Edge curling: This fabric does not curl at the edges. It is a balance fabric because of having wales in both directions. The reason is both T/F and T/B bed are active, so tension is uniform on both sides.

-

Dimensional stability: Dimensional stability is good.

-

Unraveled: We can unravel the structure from the end section only (because it forms from double bed).

-

Elasticity: Elasticity can be observed well in widthwise direction.

-

Laddering: Laddering can be repaired in flat bed knitting but not in circular knitting.

-

Density: Density is heavier than single jersey because loops catch at both sides.

End Uses:

-

-

Bottoms, collar, cuff, hem and for also for full dress.

-

Especially lightweight for undergarments because elasticity is good.

-

Double Jersey/ Interlock:

If the plain stitches are one behind the other the fabric/ structure is known double jersey.

This is quite similar in construction to the rib fabric as 1x1 rib is knitted alternately on opposite needles and it requires two knitted courses or traverses to complete one entire knitted row. Interlock is very popular on circular machines.

T/F ---- Technical Face

T/B ---- Technical Back

Properties/Identification:

1. Appearance: Both sides are same in appearance. Both technical front and technical back has V shape stitch/ jersey stitch.

Stitch diagram of Double Jersey: Loop diagram of Double Jersey:

T/B |

V |

V |

V |

V |

T/F |

V |

V |

V |

V |

2. Edge curling: This fabric also does not curl at the edges. Reason is that it is more balanced fabric because all needles are active on both sides (T/F and T/B bed). So tension is uniform on both sides.

3. Dimensional stability: Dimensional stability is very good.

4. Unraveled: We can unrope the structure from the end section only (because it forms from double bed).

5. Elasticity: In comparison to other knit fabric; (especially rib) elasticity is poor.

-

Laddering: Laddering can not be repaired in both flat bed knitting and circular knitting. Because both side needles are active at opposite direction.

-

Density: In comparison to other knit fabric; density is heavier.

End Uses:

-

Normally for heavy knitwear Vast because it is fitted.

-

Light knitted is preferred for sportswear (sports T-shirt) because it absorbs sweat well and dimensional stability is good.

-

For ladies skirt. And also for tube fabric to make pocket.

Differences between Single jersey and Rib knit:

Single Jersey |

Rib Knit |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Similarities between Single jersey and Rib knit:

-

Both is mendable (Laddering can be repaired)

Differences between Rib and Double jersey knit:

Rib |

Double Jersey |

|

|

|

|

|

|

|

|

|

|

|

|

Similarities between Rib and Double jersey knit:

-

Both side same in appearance.

-

Can be unraveled the yarn from only the end section.

-

Edge curling does not occur.

-

Both are double bedded structure. Manufacturing by using both T/F and T/B needle bed.

-

Made by two set of needle; i.e. dial needle and cylinder needle.

Differences between Single jersey and Double jersey knit:

Single Jersey |

Double Jersey |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Purl stitch:

Purl stitch, also called link-and-link stitch, is made on flat bed knitting machines and circular machines by needles using hooks on both ends to alternately draw loops to the front of the fabric in one course and to the back in the next course. The fabrics look similar on both the sides resembling back of the plain knit. Heavy, jumbo stitch is also possible which gives a bulky effect to the fabrics. However, It is comparatively slower and a costly technique. The fabric doesn't curl at the edges. Purl stitch is widely used in infant wear and kids clothing due to its crosswise stretch and excellent lengthwise stretch.

2) Warp Knitting

Warp knitting is method of fabric forming in which the loops are made in a vertical way along the length of the fabric from each warp yarns and intermeshing of loops takes place in a flat form of lengthwise basis. Warp knitting is different from weft knitting in the sense that in it each needle loops its own thread. The needles of warp knitting machines produce parallel rows of loops that are interlocked in a zigzag pattern. The stitches on the front side of the fabrics appear vertically having a slight angle. The stitches on the backside appear horizontally as floats at a slight angle. These floats are called laps or underlaps and are a distinguished features of warp knit fabrics. Warp knitting machine Warp knitting may be flat or tubular that can produce a variety of patterns. It is a very fast technique that can produce fabric with a dimensional stability almost equal to that of a woven fabric. It can also use yarns of man made fibers very efficiently. There are basically seven types of warp knitting- Tricot knit; Milanese knit; Simplex knit; Raschel knit; Ketten Raschel knit; Crochet and Weft-insertion warp. Warp knit fabrics are very popular due to their many properties such as smoothness, sheerness, wrinkle resistance, shrink resistance, strength and abrasion resistance.

Comparison of Weft Knitting and Warp Knitting

Warp knit fabrics have certain advantages over weft knits

-

Warp knit fabrics do not ravel easily.

-

They are less prone to sagging.

-

Quality is generally better than weft knits..

-

Stitch definition, texture and fabric cover are also usually better than weft knits.

-

Warp knits have superior dimensional ability.

Glossary of Knitting Terms

-

Ø Single knit: Knit fabric produced using a single set of knitting needles. It is usually a thin lightweight fabric.

-

Ø Double-knit: Knit fabric produced on two sets of opposed needles. It is thicker and heavier than a single knit fabric.

-

Ø Technical Face: The outside of the tube of fabric produced by a circular knitting machine. This may or may not be the outside of a finished garment made from the fabric.

-

Ø Technical Back: The inside of the tube of fabric produced by a circular knitting machine. This may or may not be the inside of a finished garment made from the fabric.

-

Ø Knit Stitch: An interlocking series of loops used to construct fabric. See the diagram above of the basic weft knit fabric.

-

Ø Tuck Stitch: A needle receives a new yarn without losing its old loop. A tuck loop always faces the technical back of the fabric.

-

Ø Welt, Miss, or Float Stitch: These terms describe the same formation. The stitch is created by not allowing the needle to raise high enough to receive a new yarn, causing the yarn to float behind the face stitches.

-

Ø Inlay Stitch: Combination of float and tuck stitches. In a 3x1 inlay, three needles float and one tucks. Commonly used in Fleece and French Terry fabrics.

-

Ø Jersey Fabric: The basic single knit construction (T- shirt fabric) with the appearance of tiny “V” s on the face of the fabric and wavy courses on the back of the fabric.

-

Ø Rib Fabric: This double-knit fabric draws some wales to the front and others to the back for a ridge effect. Ribs have a higher stretch and recovery than most knits and they are used for trim and body goods.

-

Ø Interlock Fabric: Two yarn feeds are required to create one course. The knitting on front and back gives interlock a smooth surface on each side of the fabric. Selected needles can be pulled out for poor boy looks.

-

Ø Lacoste Fabric: The original stitch configuration used in Lacoste shirts. The tucking pattern creates a tiny honeycomb look on the technical back of the fabric, which is used as the face for garments.

-

Ø Pique Fabric: The combination of knit and tuck stitches gives a small diamond appearance to the face of the fabric. It is the most popular fabric used in collar/placket shirts

-

Course: Row of loops or stitches running across the knit fabric

-

Wale: Vertical chain of loops in the length wise direction of the fabric, formed by one needle.

Thanks & best regards

JITU